CUSTOMER CASE

SSAB Steel Shuttle operated by VTG

Streamlining the supply chain

Every 24 hours, 3 trains in each direction between Luleå and Borlänge, Sweden. The 1023 kilometers long one-way trip is an important link in SSAB rolled steel production supply chain, annually transporting two million tonnes of slabs.

%

90% of damages detected early

Preventive shunting optimizes operations.

Optimizing VTG’s 400-wagon fleet

About 400 wagons, owned by VTG, are used in total, resulting in challenges such as:

Needs of increased reliability and availability

Optimize operational and maintenance costs

Reduce number of stops in track due to wheel damage

Ensure workshop capacity and resources in time and place

Working with Predge and using their solutions, the objectives for the Steel Shuttle were to increase the reliability/availability and reduce costs by:

Avoiding safety stops during operation due to wheel damages

Planning all maintenance activities with time and place

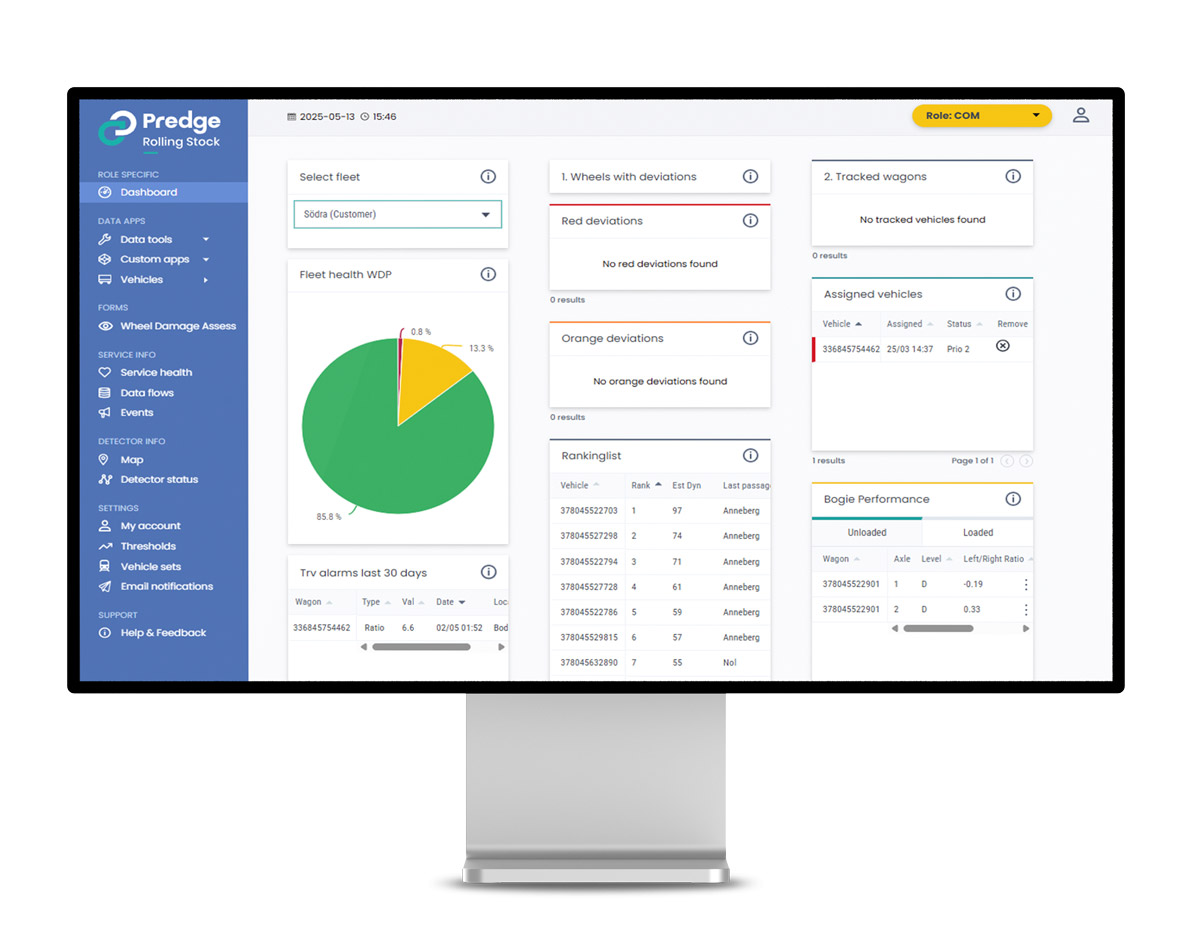

Predictive maintenance in action

By using the decision support services from Predge, the results were obvious. 90% of the damages indicated within 1200-3600 kilometers ahead, so at least one trip ahead. Thus, wagons could be preventively shunted. Further improvements for the Steel Shuttle were: