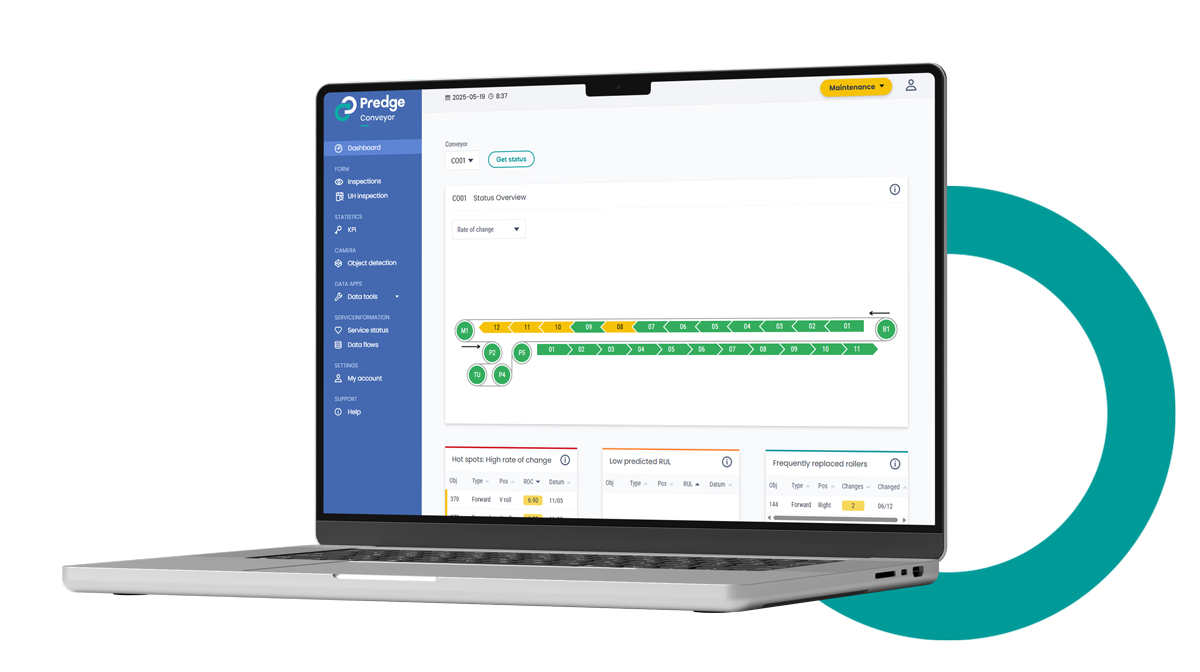

Predge Conveyor

Boost conveyor uptime with predictive maintenance. Using existing data and system design, it forecasts the remaining life of rollers, pulleys, and drives—driving smarter, data-based decisions.

OVERVIEW

Enhance conveyor performance with predictive analytics

All information is easily access through a web portal or directly communicated to other systems through standard interfaces.

Data-driven decisions

Optimize availability and efficiency with fact-based insights.

Comprehensive component analysis

Get remaining useful life, degradation rates, hot spots, and critical object detection.

Efficient access

View data via a web portal or integrate it with other systems through standard interfaces.

How we work

From data to uptime

Use of available data sources

Generates actionable insights that enhance maintenance planning, operational efficiency, and equipment reliability.

Predict remaining useful life of key components

Using data-driven analytics to prevent failures, reduce downtime, and plan maintenance effectively.

Increase availability, efficiency & safety

Turning existing data into actionable insights for proactive maintenance and optimized operations.

FEATURE

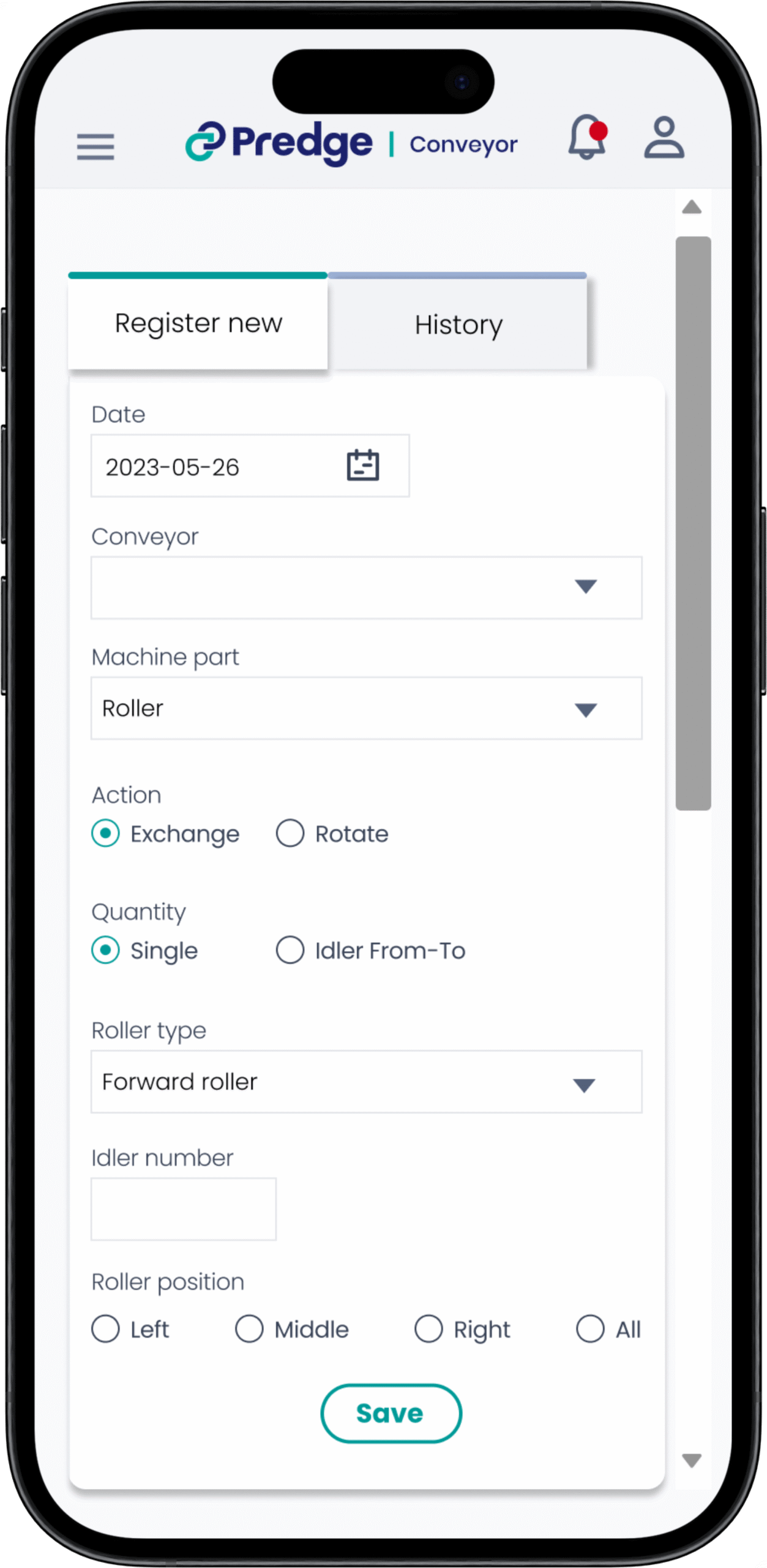

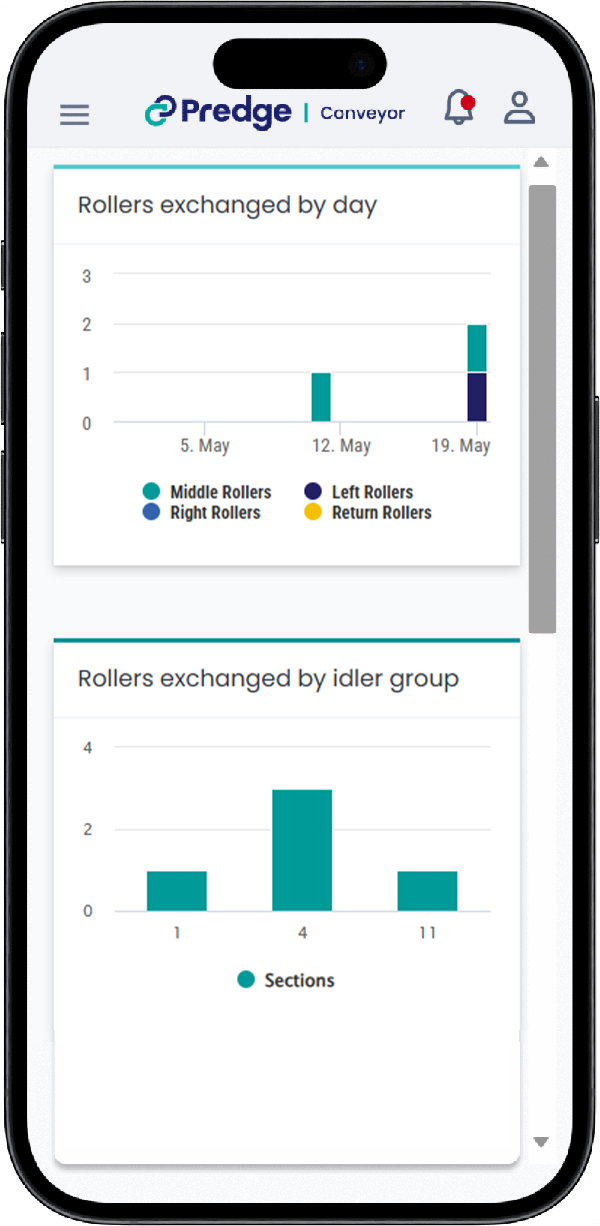

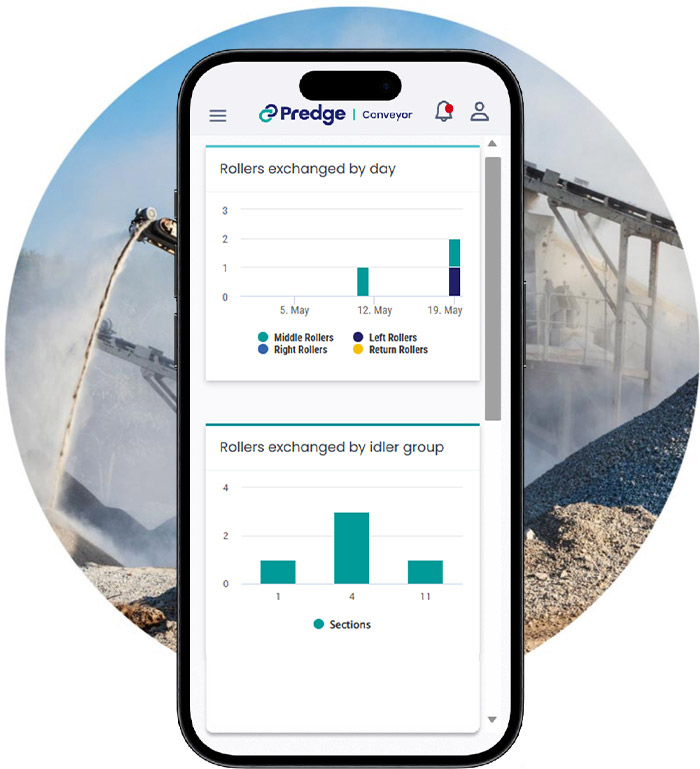

Forms

Efficient reporting forms for anomalies, inspections and component exchanges. Enables component level management as an extension of, or integrator into, your maintenance system. Track actions, follow up deviations and initiate actions.

FEATURE

Belt object detection

Boost safety. Cut downtime.

Belt object detection, cloud-integrated for efficiency, detects risks early to keep operations safe and running without disruption.

Real-time anomaly detection

Equipped with a camera, light source, and onboard processing, the system detects conveyor anomalies in real time. Detections are logged for traceability and can be reviewed to enhance accuracy.

INSIGHTS

SplAIce

In collaboration with Hosch, we provide insights on current and future conditions of specific locations on a belt, like splices, to plan inspections and maintenance actions in time.