Predge Mining

Predictive maintenance enables the anticipation of failures and the optimization of maintenance strategies, enhancing efficiency and reducing downtime through advanced technologies.

OVERVIEW

AI-powered insights for efficient and optimized mining operations

Decision support by advanced analysis for excellence in operation and maintenance.

Operational efficiency & reliability

Reduces failures, minimizes disruptions, and boosts maintenance efficiency

Cost optimization

Lowers costs, avoids emergencies, and prolongs asset lifespan

Safety & compliance

Mitigates risks and guarantees compliance through intelligent maintenance

Sustainability & ESG alignment

Optimizes energy efficiency and waste reduction with smart maintenance

Smarter Rail Operations

Enhanced maintenance for more reliable operations

Maximize equipment uptime and reduce unexpected failures with smart, data-driven maintenance strategies tailored to your operations.

Component condition prediction

Provides clear, actionable insights into the current and future condition of machine components to effectively plan, prioritize, and align maintenance actions with operational goals.

Belt object detection

Cloud integrated edge solution. Analyzes video streams from standard surveillance cameras to identify hazardous objects on belts and to alert operators for immediate actions.

SplAIce

In collaboration with Hosch, we provide insights on current and future conditions of specific locations on a belt, like splices, to plan inspections and maintenance actions in time. Learn More

>

%

Conveyor belts monitoring uptime

>

%

Hazardous object disruptions averted

>

%

Correct classified hazards

>

%

False positives

Proven results

Hazards avoided > 10000

Hazardous conditions leading to failures and safety related issues detected early on and actionable insights provided.

Proven results

Hazards avoided > 10000

Hazardous conditions leading to failures and safety related issues detected early on and actionable insights provided.

>

%

Conveyor belts monitoring uptime

>

%

Hazardous object disruptions averted

>

%

Correct classified hazards

>

%

False positives

Our solutions

Mining solutions

Our tailored solutions empowers mining operators to make data-driven decisions, improving operational efficiency and ensuring long-term sustainability.

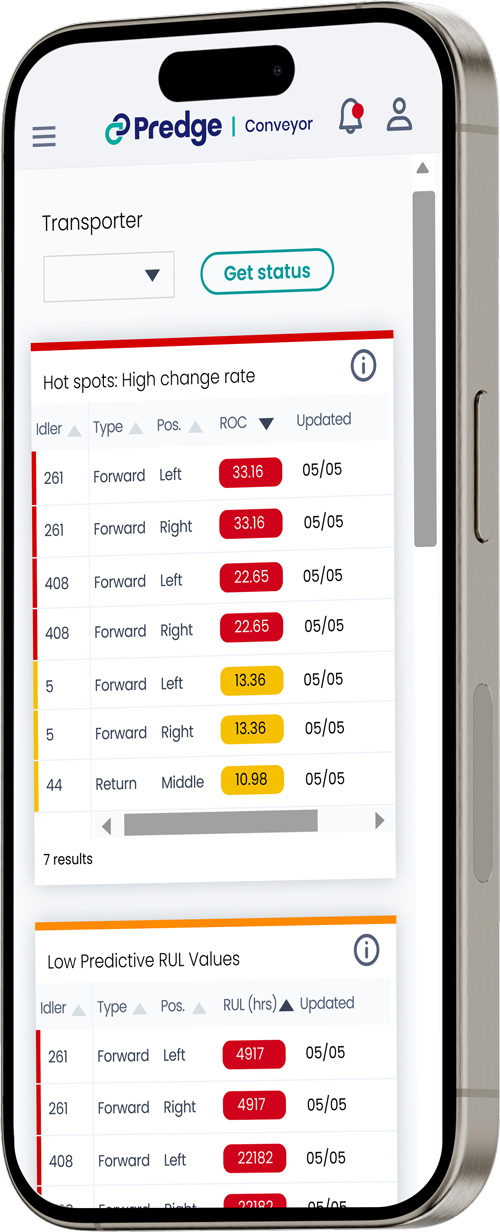

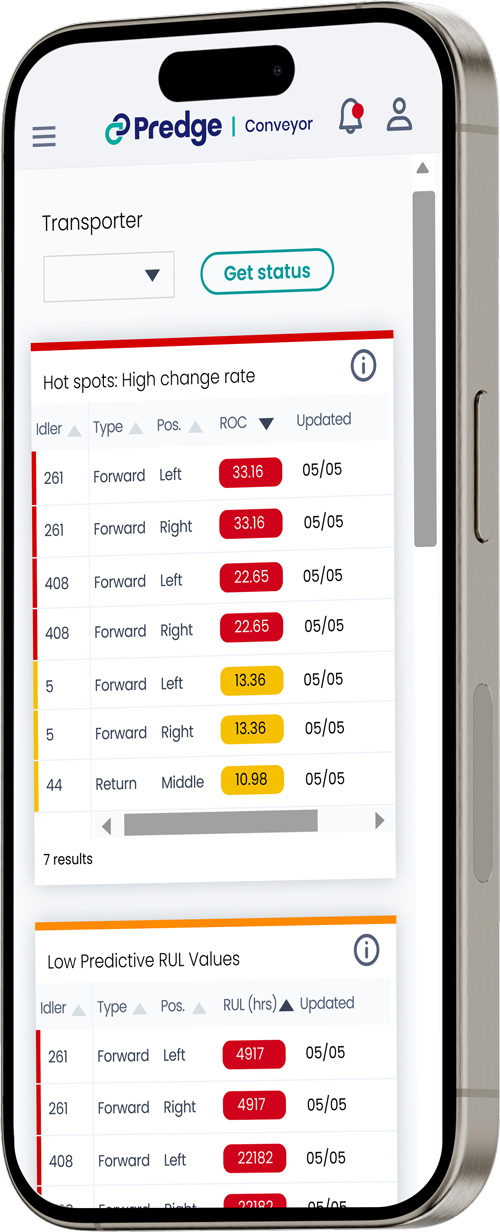

Predge Conveyor

A conveyor belt monitoring and health prediction solution using a digital twin and machine learning to predict failures and optimize maintenance.

Discover More

Forms

Efficient digital forms for inspections, assessments, and component exchanges. Turn assessments into valuable condition data today.

Discover More

Automated Work Orders

Automate and digitize tasks to streamline workflows and integrate with your maintenance system—initiate, update, and close work orders from detected or predicted events.

Discover More

SplAIce

In collaboration with Hosch, we provide insights on current and future conditions of specific locations on a belt, like splices, to plan inspections and maintenance actions in time.

Discover More

Smart Maintenance

Smarter mining, powered by AI

Predge Mining delivers AI-driven predictive maintenance that boosts efficiency, reduces downtime, and ensures safety—through a seamless, easy-to-use interface designed for smooth decision-making.