Project news

A Digital Twin for Condition Monitoring of Conveyor Belt Systems

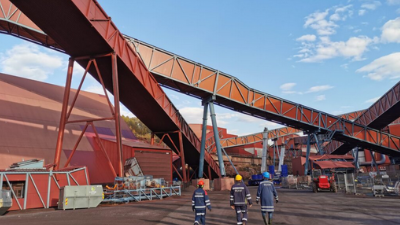

Predge AB and LKAB are jointly developing an innovative solution for condition monitoring and health prediction of conveyor belt systems, called CoCoP. A digital twin is developed and validated to provide predictive decision support for operation and maintenance of conveyor belt system. The degradation of all critical components due to wear and tear including their interactions are represented in the digital counterpart. Degradation towards failure is quantified and the time point of failure in the future is foreseen by the digital twin.

Predge and LKAB collaborate in a strategic digitalization project

Predge AB and LKAB have jointly applied for, and received, funding from *EIT RawMaterials to develop an innovative solution for condition monitoring and health prediction of Conveyor Belts. The project objective is to develop and validate an operational predictive decision support for operation and maintenance of conveyor belt systems realized on a digital platform and provisioned as SaaS. A system level approach is taken to understand wear and tear of critical components and to predict when the system will fail. The prototype uses a digital twin of the conveyor belt system combining domain knowledge with machine learning and AI principles.